All ITR GET products are engineered and designed in the Group’s R&D and Engineering departments, where technical know-how combines with extensive practical experience.Quality controls conducted by ITR personnel at the facilities of certified manufacturers and upon entry to the Group’s warehouses guarantee a high quality process and product.The ITR GET line comprises all those components required for manufacturing, reconditioning and servicing blades for bulldozers,buckets for excavators, skid loaders and loaders.The extremely varied mix includes blades, end-bits, profiles, armored bars and wear buttons, sidebar protectors for buckets,heel shrouds, lip shrouds, teeth, adapters and all those components required for excavation or leveling, like rippers or blades for graders.The ITR GET line offers solutions compatible with a wide range of models, types of machines and customized applications.

Teeth And Adapter

Tips and adapters range is suitable for all kind of machine models, from mini, medium and large excavators to skid loaders, bulldozers and backhoe loaders. By selecting the correct product the best performance is also assured on all grounds and applications.

The careful selection of the right steels, properly heat treated to ensure best overall performance and balance between hardness and durability. Rigorous quality control standards are carried out at the production facilities and manufacturing plants to guarantee the highest eve of quality.

Cutting EDGE & End Bits

ITR product range also includes blades and steel profiles product line suitable for excavators and loaders buckets, blades for scrapers, dozer blades and end-bits for all blade models.

Grader blades may be produced using standard material or using born steel in order to meet any market requirement.

Unik Teeth

ITR UNIK LINE has been conceived and designed for those applications where high penetration, impact resistance and increased wear life are essential.

UNIK presents 6 unique features:

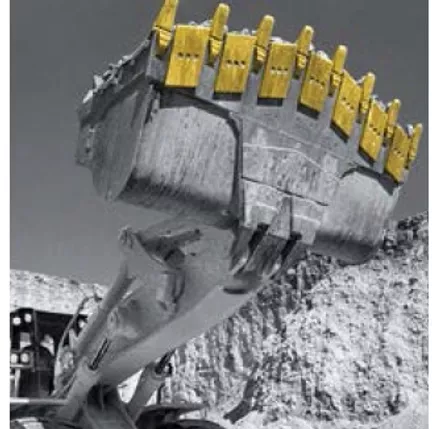

Bucket

ITR offers a product line that covers a wide range of applications. ITR buckets designed and manufactured from High strength abrasion and wear resistant steel provide the best resistance and wear life. Our full range of excavator buckets suit up to 120 tones class machines.

ITR buckets come with extensive additional internal and external plantings to withstand most hostile conditions. Buckets can be fitted with bolt-on edges, teeth and segments, corners and side-shrouds if necessary. Available in any configuration to suit most of your applications and requirements.

For extreme applications, we also manufacture Heavy Duty and Rock buckets. HARDOX super high strength wearable steel, with ITR teeth and adapters maximize product’s reliability, excavation performance and economical efficiency. These greatly reduce the time and cost of maintenance thus improving working efficiency.

Bucket Links

ITR’s heavy duty bucket linkages are developed to respond to market trends and are manufactured for a wide range of excavators.

The links are produced using Q345 plate and designed to provide excellent performance. The pin bushing can be included made from C45 steel and are heat treated to 56 Rockwell hardness to ensure the best overall performance.